|

Design

|

<< 1 2 3 >>

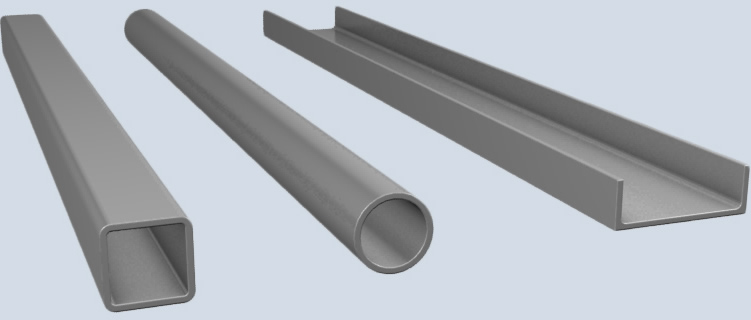

A Rectangular Hollow Structural Section, A Round Hollow Structural Section, and A Channel Section

The spatial structure components have to be fabricated very precisely as small errors in the dimensions can accumulate and result in large errors in the final overall dimensions of the structure. The members are typically cut to length to a tolerance of about 1/25 to 1/50 inch. When different pieces have to be welded to each other (such as the cone-shaped end pieces in Mero members), precisely dimensioned jigs are used to make sure that the overall lengths are within the required tolerance. In addition, the connectors are manufactured with similar or even better accuracy, with holes and/or slots placed at the exact locations and angles.

<< 1 2 3 >> |

<<Design Index <<Back to Knowledgebase |